A team of bioengineers, led by the Wake Forest Institute for Regenerative Medicine, receives up to $24.8 million over five years from the Advanced Research Projects Agency for Health (ARPA-H). Rice University bioengineer Antonios Mikos contributes to this effort aimed at tackling the organ donor shortage through on-demand bioprinted kidney tissues.

Developing Vascularized Kidney Tissue

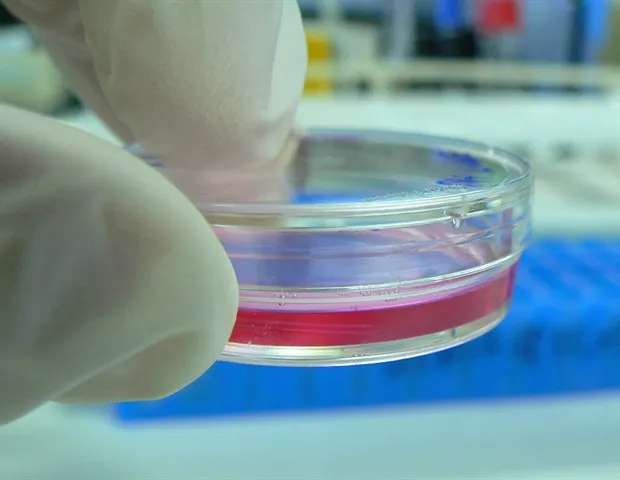

The initiative focuses on creating bioprinted, vascularized kidney tissue that enhances renal function for patients with kidney disease. Engineers craft this implantable tissue from a patient’s own cells mixed with specialized bioink to ensure long-term cell viability.

“Our key efforts center on developing bioinks—3D-printable inks that host cells,” explains Vasiliki Kolliopoulos, a postdoctoral researcher in the Mikos lab. “These complex materials must mimic the tissue microenvironment and sustain cells throughout their culture before implantation.”

Researchers plan to build a library of adaptable bioinks for various patients while vascularizing 3D-printed structures to support sustained function in the body. The Mikos group leverages its expertise in tissue-mimicking bioinks, bolstered by resources at Rice’s Biomaterials Lab.

ARPA-H’s PRINT Program

This funding stems from ARPA-H’s Personalized Regenerative Immunocompetent Nanotechnology Tissue (PRINT) program, part of the U.S. Department of Health and Human Services. PRINT employs advanced bioprinting and regenerative medicine to produce personalized human organs that eliminate the need for immunosuppressive drugs.

The program addresses critical U.S. challenges: over 120,000 people await organs, yet only about 45,000 transplants occur yearly. Transplanted organs typically last 15 to 23 years and demand lifelong immunosuppressive therapy.

“Tissue engineering converges multiple disciplines, and ARPA-H mechanisms like PRINT unite labs and institutions with diverse expertise to solve major issues like kidney disease,” states Mikos, Louis Calder Professor of Bioengineering and Chemical and Biomolecular Engineering, and director of Rice’s Biomaterials Lab, Center for Excellence in Tissue Engineering, and J.W. Cox Laboratory for Biomedical Engineering.

Collaborations and Path to Commercialization

The project builds on longstanding partnerships among Rice University, Wake Forest Institute for Regenerative Medicine, University of Maryland, PrintBio Inc., and University of Texas at El Paso.

“We’re excited to join this pivotal project and advance next-generation patient care,” adds Kolliopoulos.

Plans include scalable manufacturing and commercialization of personalized bioprinted organs and tissues. “PRINT demands breakthroughs in cell manufacturing, bioreactor design, and 3D-printing to create functional organs,” notes Ryan Spitler, ARPA-H PRINT program manager. “Success could slash wait times, end lifelong drug needs, and pave the way for bioprinted solutions across other organs.”

![[Two Pronged] A lonely spouse offers with homesickness, communication points [Two Pronged] A lonely spouse offers with homesickness, communication points](https://www.rappler.com/tachyon/2026/02/two-pronged-lonely-wife-deals-with-homesickness-communication-issues.jpg)